Polyflon offers high quality, bespoke thermoformed tubing, tube assemblies and thermoformed thin film diaphragms.

Custom 2D tube shapes can be formed using in-house tooling; pre-formed articles can then be finished with flanges, flares, cuffs, or plugs. Existing standard tooling inventory allows us to offer retractable coils in many different configurations to satisfy most applications, however, custom retractable coils are always possible.

Specialist markets for our thermoforming and assembled products include pharmaceutical, bio-tech, instrumentation, environmental monitoring & analysis, oil & gas and semiconductor. Most materials satisfy FDA regulatory requirements and enjoy USP Class VI approval.

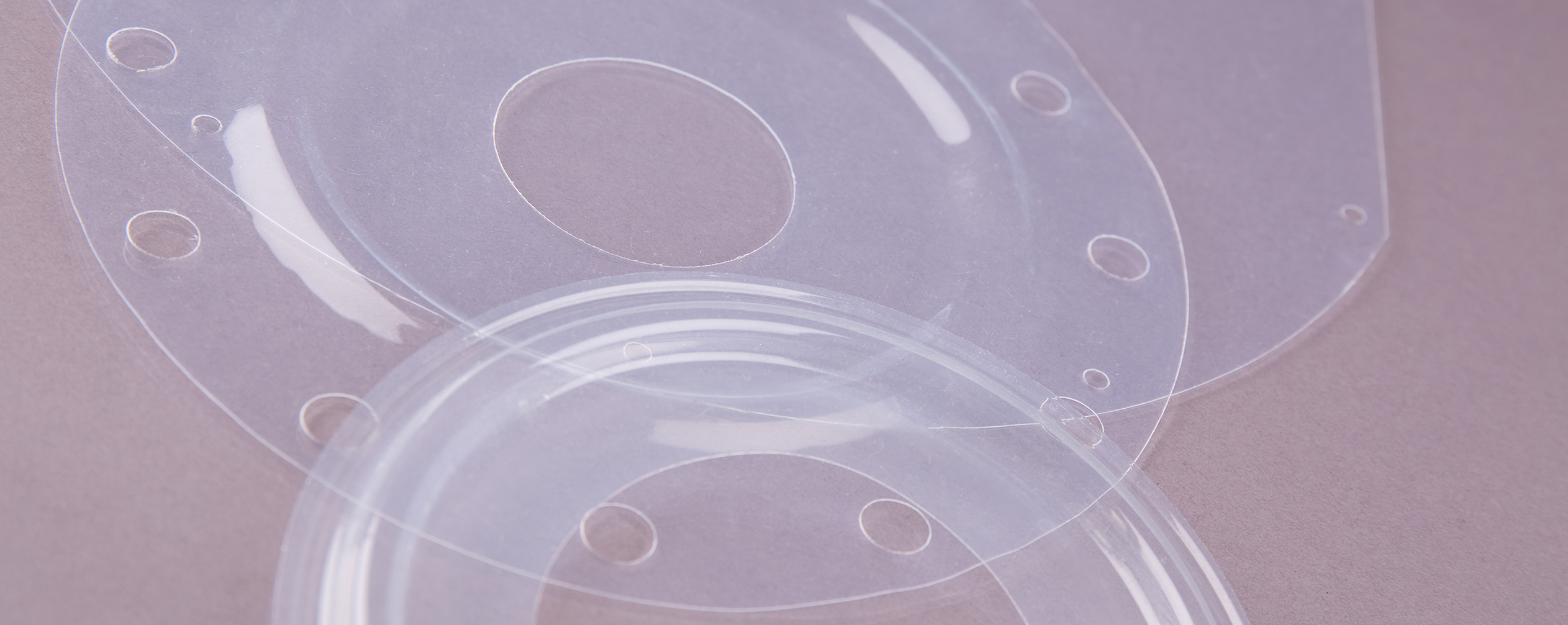

Machined vessel lid seal

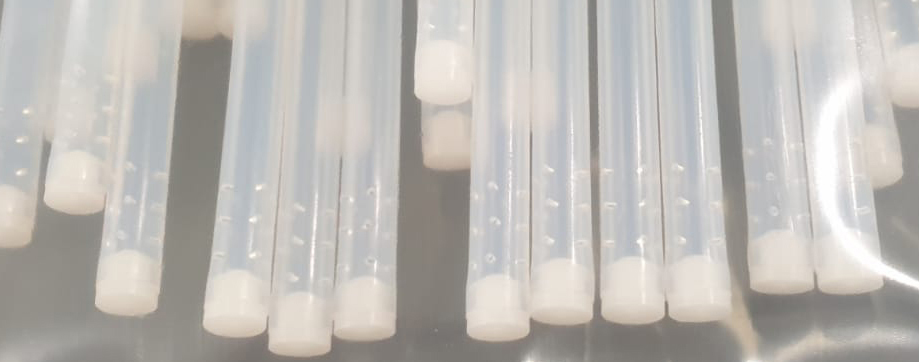

Drilled PFA Tubing with plug

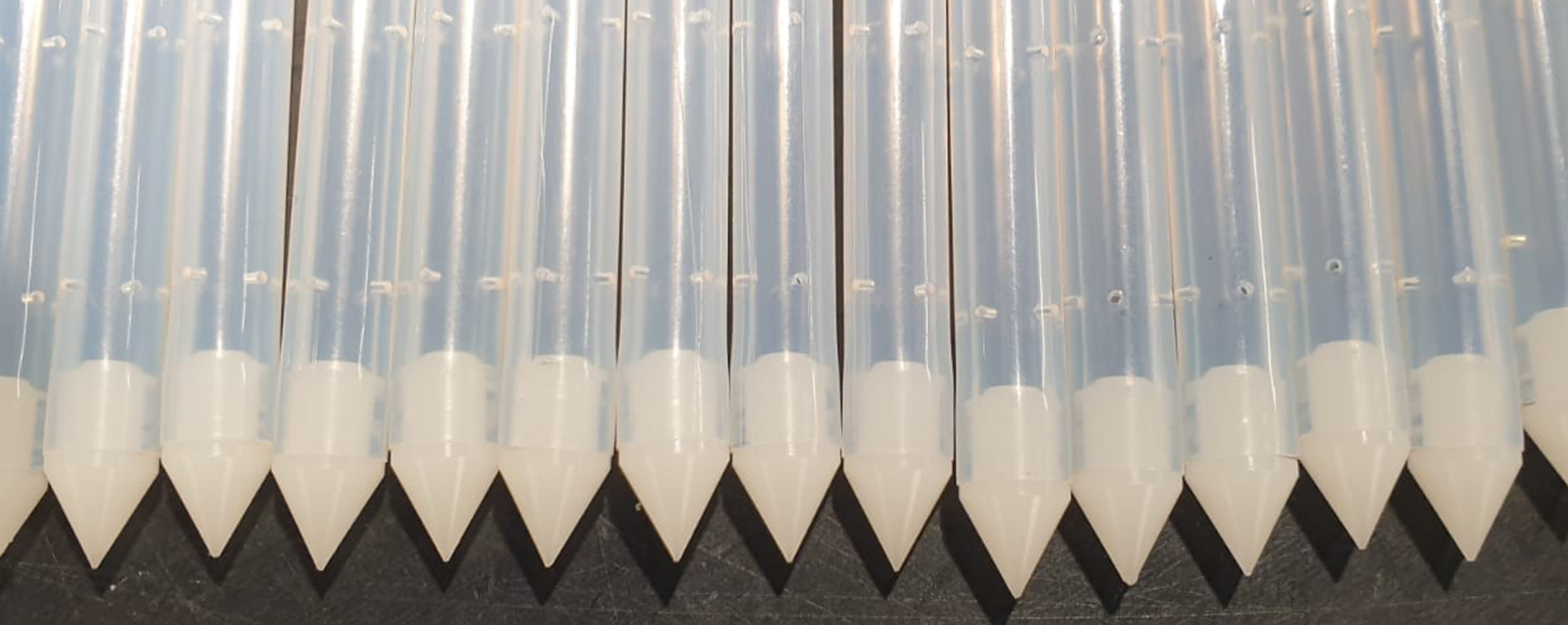

Drilled PFA Tubing with pointed plug

FEP Tubing with Luer Lock Connector

Pre formed & Flared FEP Tube & Assembly

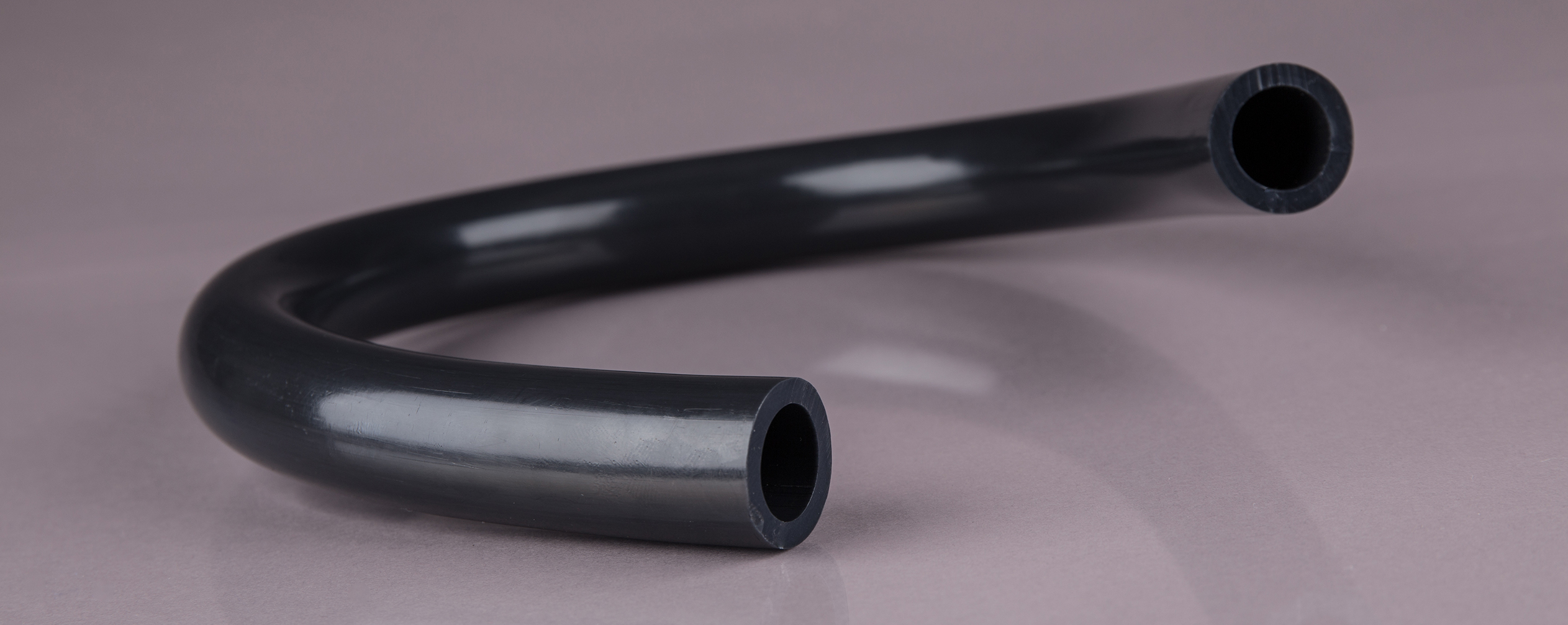

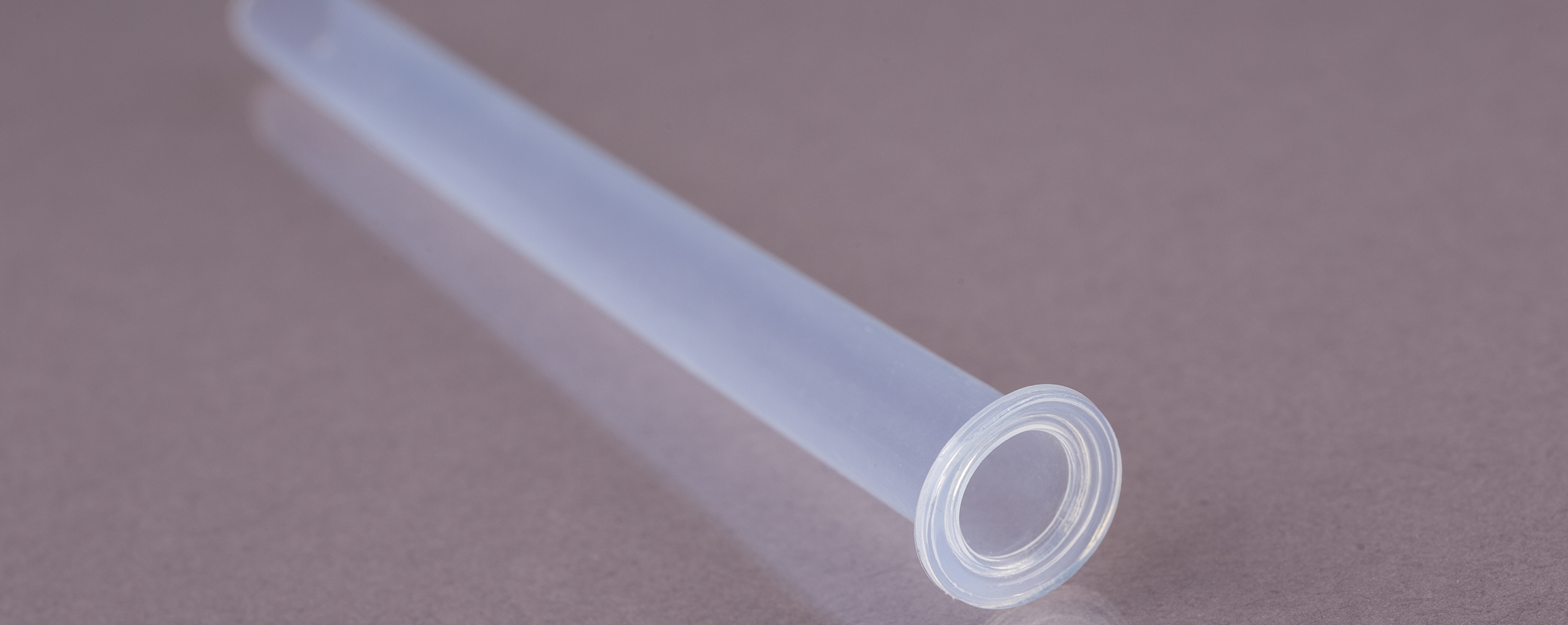

Modified PTFE Pre Formed Tube

Peristaltic Pump Tube Assembly

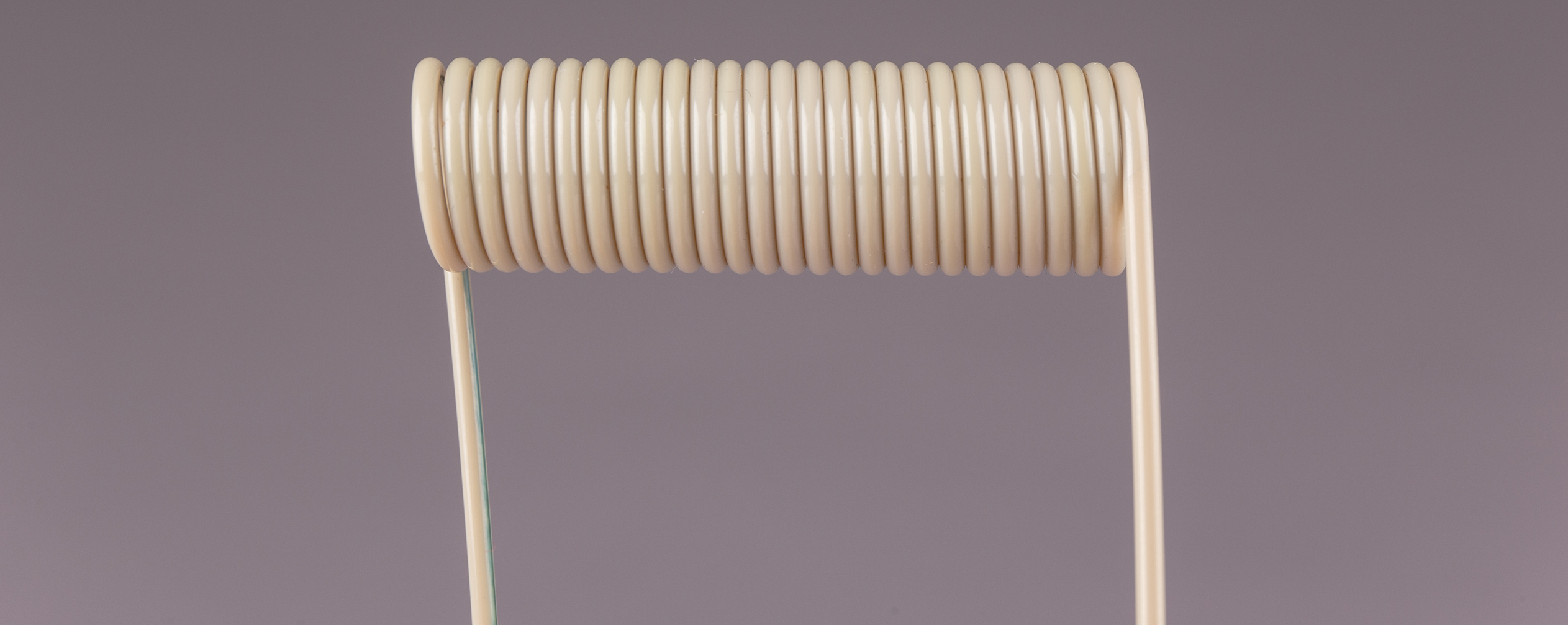

PEEK Extension Coil

Flared FEP Tube

Compression Formed FEP & ECTFE Diaphragms

FEP Retractable Coil & Fitting Assembly

Flared PFA Tubing

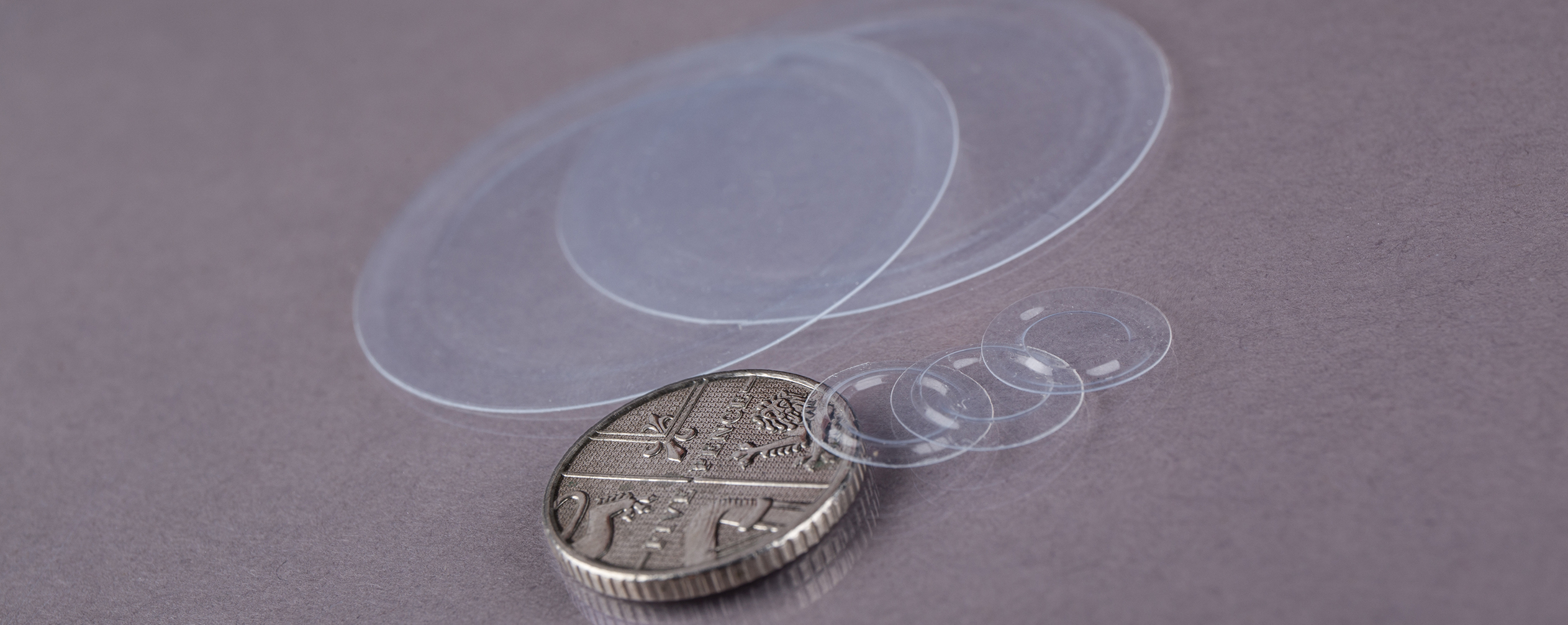

Compression Formed FEP Micro Diaphragms

Pre-Formed FEP Tube

Retractable Semi-Crystalline PEEK Coil

Micro Moulded Tube Tip

PTFE Cuffed & Convoluted Tube

We offer a wide range of standard tubing connectors in PVDF, PFA, PTFE, Aluminium and Stainless Steel to connect to any straight cut tubing, pump tubing or thermoformed tubing to create custom tube assemblies.

Additional processes we perform are machining, drilling, slitting, high speed cutting, manual precision jig cutting and spiral cutting.

We also offer thermoformed and assembled products specifically designed for use in medical devices, all produced in our Class 7 clean rooms. You can visit our dedicated Polyflon Medical site here: www.polyflonmedical.co.uk.

Polyflon's punched parts are produced from sheet, tape & film in such diverse materials as ePTFE, standard PTFE, FEP, PFA, PVDF, ECTFE, ETFE, FPM, PET, EPDM, Nitrile & Silicone.

Read moreGet in touch with our experienced team to discuss your Fluoroplastic requirements. Simply click the button below to send us a message or call us on +44 (0)1785 859 054.

Get in touch